Atom Dynamic’s Unique Advantage

Demanding industries -oil, gas, energy and utilities companies- where care and management of assets is paramount, trust ATOM DYNAMIC as their provider and partner.

Our expertise covers an asset’s entire lifecycle -from research and construction to production and operation- while our services and solutions ensure quality control, safe operation and production, aiming to extend an asset’s lifecycle.

Our holistic approach takes into account the asset’s reliability and its integrity. We help customers optimize their efficiency, reduce costs and maximize performance while minimizing operational and regulatory hazards. We also help constructors comply with international standards and customer specifications.

Our worldwide reputation and the values governing our operations, such as top quality and safety of services and our commitment to delivering under highly exacting circumstances, have made us an indispensable, preferred partner of a large number of demanding customers on ND testing services and inspection.

Our major advantages in an Inspection project are based upon experienced project managers with a customer-centric culture, a sense of priority and urgency, respect for deadlines and scheduled timelines and a focus on providing constructive feedback throughout the project’s lifecycle.

Moreover:

- Experienced, highly-trained and qualified NDT technicians and inspectors with the physical endurance and respect of customer’s needs and assets’ value; a mandatory requirement for such a critical service

- Calibrated and well-serviced equipment that ensures quality of service in line with international specifications

- Reasonable and cost-efficient pricing

- Administrative and technical support throughout the project’s lifecycle

- An exceptional program for human resources’ safety and environmental protection

- A strong corporate relationship with each and every client by being a trusted part of the customer’s extended project team

- Immediate and courteous customer service whether the requirement is a single weld, a short term plant maintenance shutdown project, long term major plant construction, one-off vessel or tank fabrication or a highly specialized requirement

ATOM DYNAMIC provides a variety of different gamma and X-ray services. From typical g-ray exposures to panoramic crawler shootings, we are capable of supporting the entire applicable range of any joint configuration, from small-bore welded products of ½’’ to the highest diameter pipeline, with either gamma-ray or X-ray beams.

Our huge variety of products and equipment make ATOM DYNAMIC a leader in the market of service providers worldwide. Moreover, the introduction of radiograph film digitization into major utilities, such as construction and industrial projects, enables the owners of plants, private enterprises of power/petrochemical processing and pipelines to keep electronic records in permanent archives.

ATOM DYNAMIC supports these services with many different options. These electronic records satisfy all legal rules and international standards. The longevity of the NDE data life ensures that all information becomes part of the product lifecycle of that entity.

MUT may be used for the inspection of piping configurations, vessels, and structural steel. It is a quick, non-intrusive and cost-effective examination which turns to a most reliable inspection method in the hands of our experienced, certified specialists.

With the use of shear waves (angle beam) we can detect flaws vertical to the beam of the ultrasound echo, which means defects such as lack of fusion or inadequate penetration, cracks or other linear discontinuities are easily found.

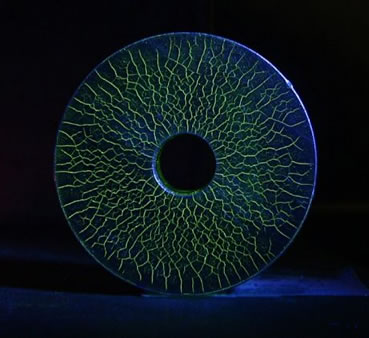

ATOM DYNAMIC is the leader in variable applications of eddy current testing.

We have highly educated specialists with the most extensive experience; when it comes to understanding your needs we can be your trusted advisor./p>

For any variable application of eddy current examination or simply for advice, you can count on ATOM DYNAMIC to provide a complete inspection solution that will help and cover all your needs.

DIRECT VISUAL INSPECTION

Certified under international standards EN ISO 9712 and SNT TC 1A, our inspectors can undertake visual examination services, covering any client’s needs and any specific project requirements.

INDIRECT VISUAL EXAMINATION

ATOM DYNAMIC maintains a significant number of equipment and tools applied to indirect visual examination, such as state of the art flexible endoscopes for penetrating confined locations and rigid boroscopes for specific applications. We specialize in the accessibility of the most difficult locations.

MANUAL MAGNETIC PARTICLES EXAMINATION

ATOM DYNAMIC offers magnetic particles examination, both with visible and fluorescent light. The quality of our services is guaranteed by our years-long experience and the large number of inspectors certified under different international standards.

DYE PENETRANT TESTING SERVICES

ATOM DYNAMIC’s inspectors have been trained and certified for the implementation of this very useful, quick and significant NDT method. Our services include both the visible and the fluorescent dye-penetrant method.

HOLIDAY TESTING / PAINTING TESTING

Where piping configurations, pipelines or structures coated with non-conductor coatings or painting are in existence, there is a need to detect unacceptable discontinuities such as pinholes and voids. Holiday testing or continuity testing is one of the extra services we provide; a variety of instruments are available for this.

VACUUM TESTING

Vacuum box testing is the principal method for testing tank floors/roofs and special requirements on piping arrangements for leaks or throughout pinholes. ATOM DYNAMIC’s inspectors can offer the most reliable results on this inspection technique with the use of a variety of different vacuum boxes.

PEEL TESTING / PAINTING THICKNESS GAUGING

Peel testing is a method which helps characterize adhesive bonds. It is used extensively to evaluate the bonding strength of tapes, adhesive and flexible substrates including rubber, films and other types of coating. With portable instruments ATOM DYNAMIC inspects the quality of the application of an adhesive under specific client’s requirements. Moreover, we offer painting and coating thickness-gauging giving a quick solid result.